|

|

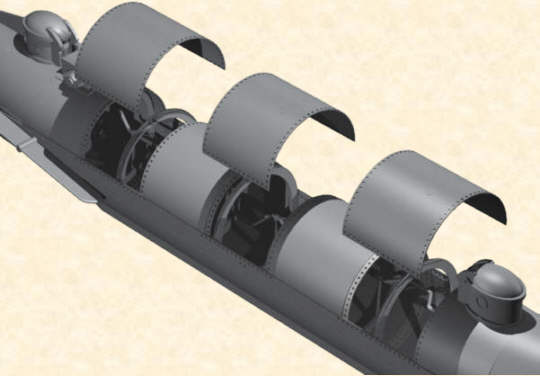

he central hull, comprising the three panels first removed, the two intervening panels and the snorkel box panel, appears to have uniform dimensions along its length. Each of these panels is semi-cylindrical, as illustrated below. |

|

|

|

| The central hull is described historically as a converted locomotive boiler, but Andrew Hall offers the very plausible alternative that if secondhand plates were used, they were more likely from a steamboat boiler shell. He indicates there was some manufacture of Western Rivers steamers at Mobile, Alabama at the time of the Hunley's construction there. Andrew led a project that documented the boiler of the steamboat Mary Conley, built at Mobile in 1865. He tells us that Western Rivers steamboats like Mary Conley had two or more boilers, typically 22-27 feet long and 3 to 3½ feet in diameter. It's clear from Andrew's illustration below that one of these boilers would have provided enough plates for the Hunley's central hull. | |

|

|

|

|

|

|

|

(Boiler Graphics courtesy of Andrew Hall) As detailed at right and in the inset above, the boiler construction is radically different from the Hunley. There was no need for hydrodynamic streamlining. The only design requirement was sufficient strength against bursting. |

|

| Although somewhat more complicated than in the graphic, the plate edges overlap and the courses are staggered so there is no seam running the length of the boiler. It's clear that a boiler was not simply cut in half, but plates from a disassembled existing boiler or intended to be assembled into a boiler could have be used for the Hunley with very little modification. The exploded view graphic of my reconstruction, below, shows how the addition of strakes to increase the cabin height and rivet plates to back the new butt joints could use plates like those above. | |

|

|

|

|

|

|

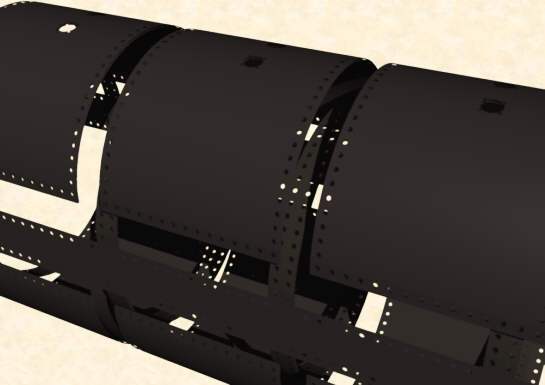

| The hull plates do not overlap but are riveted to a circumferential band located below the plate butt joints. The lower edge of each plate fits behind the extension strake that runs along each side of the hull. Rivets were inserted from within the hull and smoothed on the outside. |

|

|

The rivet holes in the plates are countersunk and the rivets

are nearly invisible from outside. They do not show at all on the still attached

plates in some of the reconstruction graphics. The result is a highly

streamlined surface. |

|

Another Possibility Kevin Wilcomb,

who has worked with steam locomotive boilers for many years, revisits the

locomotive boiler origin of the Hunley

hull plates. He offers that the

countersunk rivets were perhaps not for streamlining but rather the result

of available materials. Locomotive

boiler plates of that era had single-rivet row, lapped seam plates, riveted

together in the usual, button-head fashion.

Locomotive boiler side and crown sheets, however, were riveted with

countersunk, flush-mounted rivets to prevent the fire from damaging the

rivet head and causing leakage and or total failure. Since fireboxes wore

out faster than exterior boiler shells, more would be available for

recycling. The general hull plate size is consistent with a firebox

side sheet. Using discarded

firebox sheets might account for both the locomotive boilers legend and the

countersunk rivets on her hull. |

|

Plate Dimensions I determined the reconstruction central hull plate lengths by examining published photos and web cam views. The first panel removed shows 15 rivet holes along its edge. The second and third plates removed each have 16 rivet holes, as does the later removed snorkel-box plate. Rivets are not discernable on the remaining plates, but their widths relative to the removed plates can be estimated by photo examination. My guess is that the plate aft of the middle opening has 15 rivets and the one forward has 16. I originally used a reported 33-inch length for the middle plate to determine all panel dimensions. This analysis appeared foolproof until the snorkel-box plate was removed and revealed to be similar in size to the others. The National Park Service Site Assessment Report gives the distance between the two hatches as 16 feet 3 inches. Using the reported 33-inch size, the total length of all six plates spanning the space between the hatches is too large by a foot. There are a number of possible explanations for the discrepancy: |

|

| As an official survey report, the site assessment is unlikely to have a gross error. Field measurements are usually made more than once to assure correctness. The Friends of the Hunley have released a low resolution drawing of the sub, made from information gathered in the lab, that is consistent with the assessment report numbers. My conclusion is that the 33-inch length report is wrong. Working backwards, the length needs to be closer to 30 inches. This change affected all of the central section, the placement of the frame rings, and parts of the ballast tank sections. (A later, independent account supports this 30-inch dimension.) |

| Reports state the first plate was held by 94 rivets and the second by 96. If the count is only of the rivets in the plate, and does not include those drilled out on the expansion strake just forward and aft of the plate, then each plate has a total of 34 rivets going over the top of the sub from horizontal edge to edge. |

|

What do you think? |

This page and its contents,

except as noted,

Copyright © 2005, 2006 Michael & Karen Crisafulli.

All rights reserved.

16 Apr 06